An auto connector mould is a specialised tool used in the production of automotive connectors. These connectors are essential components in modern vehicles, allowing for the secure transmission of electrical signals and power between various systems. The practicality of an auto connector mould lies in its ability to produce these parts with consistency, efficiency, and precision.

One key practical advantage of using an auto connector mould is consistent quality. Through the injection moulding process, molten plastic is shaped into precise forms that meet the technical requirements of automotive connectors. These components need to fit perfectly and maintain reliable electrical contact, and a well-designed mould ensures each part meets those standards.

Another important benefit is high production efficiency. The use of moulds allows manufacturers to produce connectors in large quantities, helping to meet the high demand of the automotive industry. Moulds can be designed with multiple cavities, allowing several parts to be produced in each cycle, which improves output and reduces manufacturing costs.

Durability and performance of the connectors are also influenced by the mould. The injection moulding process ensures that each connector has the necessary structural integrity to withstand the demanding conditions found in vehicles, such as vibration, temperature changes, and exposure to moisture.

Additionally, auto connector moulds offer flexibility in design. They can be customised to produce connectors of various shapes, sizes, and configurations, which is important given the wide range of electrical systems in modern vehicles. This adaptability allows manufacturers to meet specific needs for different models and applications.

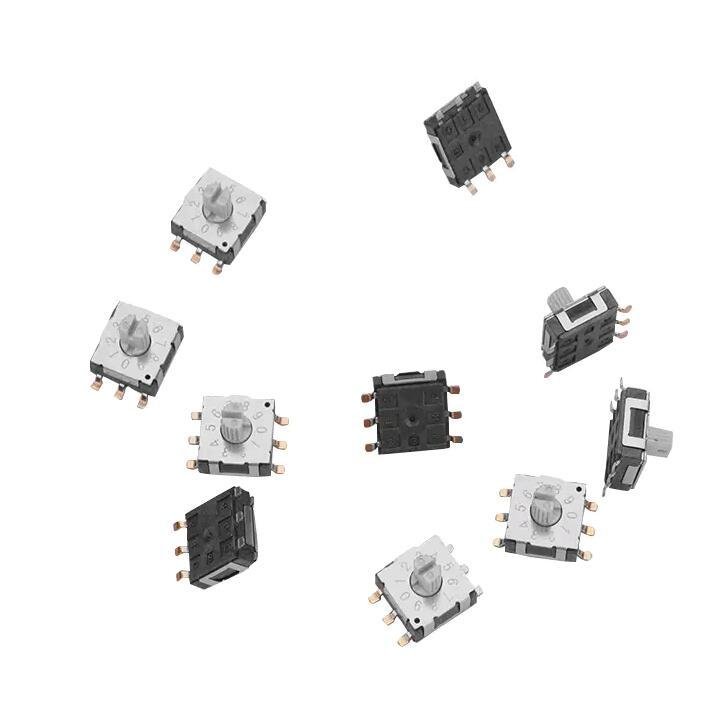

https://www.automobiletiemould.com/product/automotive-connector-mold/multiposition-small-ultrathin-rotary-straight-side-plugin-coding-switch-automotive-connector.html

Precision of the whole mold can reach 0.005mm Discharge machining accuracy tolerance up to 0.003mm

Precision of molding injection products can reach 0.02mm Discharge clear angle up to 0.01mm

Mould life time 2 million times Mirror discharge finish up to Ra0.2