ball valve assembly machine How thick is the guide rail plastering? This is the ball valve assembly machine purchase and want to know people want to ask questions, in fact, different manufacturers of guide rail plastering thickness is not uniform and can not be generalized, today we on the machine tool plastering guide rail and paste process to do a detailed explanation, I hope to help you.

Plastic pasted guide rail is the use of adhesive polytetrafluoroethylene guide soft tape bonded to the guide rail surface, so that the traditional friction form of the guide rail into cast-iron plastic friction pair. (Hereinafter referred to as the guide soft belt polytetrafluoroethylene plastic guide soft belt)

(1) Where is the guide soft belt used

The soft belt of the guide rail is generally fixed on the short guide rail (moving guide rail or upper guide rail) of the sliding guide rail, so that it can slide with the long guide rail (static guide rail or lower guide rail), such as the lathe can be attached to the bed saddle guide rail or the tail seat guide rail, as well as the iron guide rail.

(2) polytetrafluoroethylene guide soft belt

Polytetrafluoroethylene guide soft belt is made of polytetrafluoroethylene as matrix, adding copper powder, molybdenum disulfide and graphite filler mixed sintering to make the guide soft belt. The characteristics of polytetrafluoroethylene guide soft belt are:

⑴ Good wear resistance

The static and static friction coefficient is basically close, and the friction factor is very low, which can prevent the crawling at low speed and make the movement smooth. Because the soft tape material of polytetrafluoroethylene plastic guide rail has lubricating effect itself, the oil supply requirement is not high, and the intermittent oil supply can be used.

⑵ Good vibration reduction performance

The damping performance of plastics is good, and its vibration and sound damping performance is of great significance to improve the relative motion speed of friction pairs. The maximum feed speed can reach 15m/min.

(3) Good process performance

It can reduce the requirements on the hardness and surface quality of the metal matrix of the plastic paste, and the plastic is easy to process (milling, planing, grinding, scraping) to obtain good guide surface quality.

(3) Adhesive

The adhesive used for soft tape bonding of polytetrafluoroethylene guide rail is the guide rail adhesive. There are two main categories: fluorine-free guide rubber and fluorine-containing guide rubber. Fluorine-free guide rubber has domestic F-4S,F-4D,FS and other grades.

J-2012 guide rail adhesive is a two-component epoxy resin adhesive, which can be cured at room temperature or by heating. It is not only suitable for fluorine plastics and metals, but also for bonding and repairing metals and other non-metallic materials. The adhesive has good bonding strength, oil resistance, alkali resistance, water resistance and aging resistance.

Guide soft tape paste technology

Preparation: The bonding site should be clean and dust-free. The ambient temperature should be 10-40 ° C and the relative humidity should be <75%. The soft belt is treated with sodium naphthalene on one side, the dark brown side is the bonding surface, and the blue green side is the working surface. The remaining soft tape and special glue should be kept away from light and moisture. In order to improve the bonding strength, the surface roughness of the bonding surface of the metal guide rail is optimized to be Ra12.5 ~ 25μm (finish 3 ~ 4). The matching guide rail should be slightly wider than the soft belt guide rail, and the surface roughness should be Ra0.8 ~ 1.6μm (finish 7 ~ 8).

Cutting: The cutting size of the soft belt can be put some allowance according to the actual size of the metal guide rail bonding surface, and the width side can be put 2 ~ 4mm to prevent slip when pasting; Each side of the length can be placed 20 ~ 60mm, easy to pull both ends tightly when pasting.

Cleaning: Before bonding, rust and oil should be removed from the bonding surface of the metal guide rail. Rust spot impurities can be removed with emery cloth, sandpaper or steel wire brush, and then scrubbed with acetone and dried; If the oil stain of the old machine tool is serious, it can be washed with NaOH lye first, and then scrubbed with acetone; If conditions exist, the metal rail bonding surface can also be sandblasted. At the same time, scrub the dark brown adhesive surface of the soft tape with acetone and let dry for use.

Glue: Special glue must be used with the weight ratio of component A/component B =1/1, weighing and mixing, stirring evenly can be coated with glue (see bottle label instructions).

Gluing: Gluing can be done with "toothed scraper" or 1mm thick formica sheet. Special adhesive can be applied vertically on the metal guide rail, transverse coating on the soft belt, the coating should be uniform, the adhesive layer should not be too thin or too thick, the amount of glue can generally be controlled at 700g/m² The thickness of the rubber layer should be controlled between 0.08 and 0.12mm.

Paste: When the soft belt is just pasted on the metal guide rail, it needs to wriggle around before and after to make it fully contact; Squeeze by hand or appliance from the center of the length of the soft tape to both sides to remove air bubbles; For large and medium-sized machine tools, BOPP sealing tape can be pasted and positioned.

Curing: curing at room temperature, curing time: 24 hours, curing pressure: 0.06 ~ 0.1MPa, the pressure must be uniform, the weight of the machine table itself can be reversed on the guide rail of the bed, and then the weight if necessary. Products on batch use, can also be customized pressed iron to do the pressing parts. In order to avoid the extruded residual glue sticking to the bed guide rail, you can lay a layer of oil sealing paper or paint a layer of oil on the bed guide rail surface in advance.

Processing: After curing, the workbench should first be pushed along the direction of the guide rail, and then lifted and turned, remove the residual glue, and cut the process margin of the soft belt along the direction of the bonding surface of the metal guide rail and chamfer. Soft belt has good scraping performance, can be ground, milling or manual scraping to the accuracy requirements, machining must be fully cooled by flooding coolant, and the amount of feed should be small; Scraping can be carried out according to the usual scraping process, and the contact surface can be uniform up to 70%. However, it is recommended that the oil groove generally not open through the soft belt, the depth of the oil groove can be 1/2 to 2/3 of the thickness of the soft belt, and the oil groove is at least 6mm away from the edge of the soft belt.

The above is the machine tool plastering guide rail and paste process, this process is in the CNC machine tool guide rail plastering thickness has been determined on the basis of operation, for people who want to buy CNC machine tools, ball valve assembly machine guide plastering thickness is related to the accuracy and service life of the machine tool, strictly prohibited treatment is understandable, After all, the purchase of machine tools is a big deal, our buyers not only to understand this but also to understand the ball valve assembly machine other structures, such as the system, guide hardness, clamp, etc., comprehensive comparison and then make the final decision.

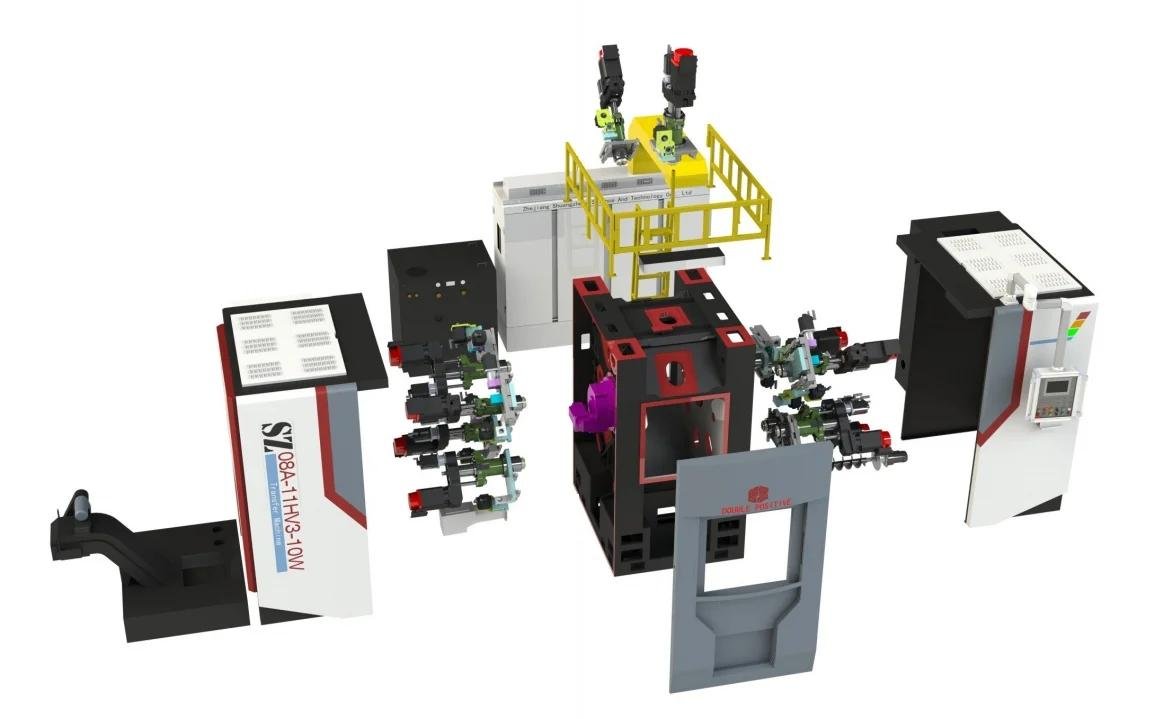

ball valve assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html