In pharmaceutical packaging, extractables and leachables refer to chemical substances that might migrate from the stopper material into the drug product. Butyl rubber stoppers for medical use undergo rigorous testing to minimize these risks, ensuring the safety and efficacy of the medication throughout its shelf life.

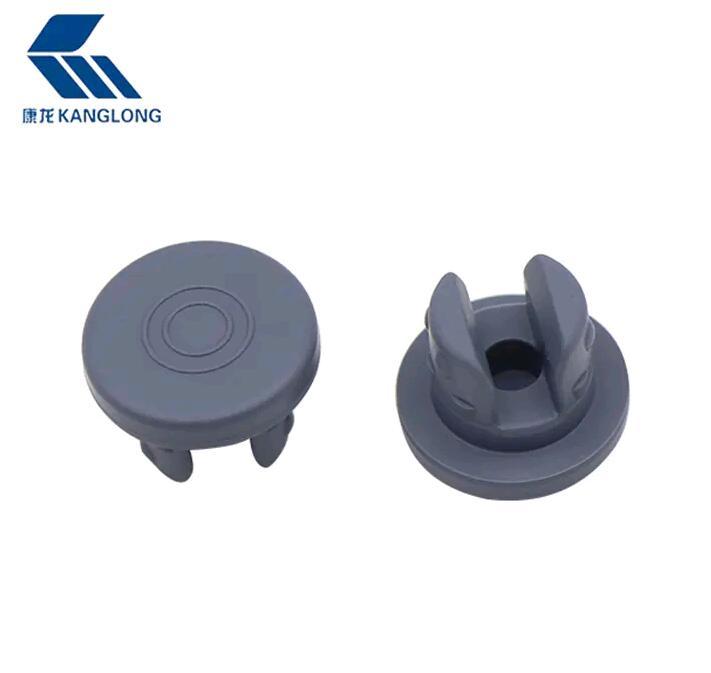

Applications of Medical Lyophilization Freeze-Dried Butyl Rubber Stoppers

Freeze-Dried Vaccines: Many vaccines require freeze-drying for stability, and butyl rubber stoppers ensure the vial remains sealed and sterile during storage and transportation.

Biological Drugs and Peptides: Sensitive biological molecules often degrade in liquid form but remain stable when freeze-dried and sealed with proper stoppers.

Injectable Pharmaceuticals: These stoppers are widely used in injectable drug vials, maintaining sterility and preventing contamination during handling.

Diagnostic Reagents: Freeze-dried diagnostic agents stored in sealed vials require reliable sealing to preserve their efficacy.

Advantages Over Other Materials

Compared to other rubber materials such as natural rubber or silicone, butyl rubber provides superior impermeability and chemical inertness, making it a preferred choice for demanding medical applications. While silicone stoppers offer flexibility and inertness, they typically have higher gas permeability and less chemical resistance than butyl rubber.

By meeting strict medical standards for biocompatibility and cleanliness, these stoppers help maintain product sterility and integrity from production through administration. As pharmaceutical technology advances, the importance of reliable, high-quality stoppers like those made from butyl rubber will continue to grow, supporting safe and effective drug delivery worldwide.

https://www.klstopper.com/product/pharmaceutical-rubber-stopper/lyophilization-freezedried-butyl-rubber-stoppers.html

Excellent sealing performance

Replacement of barrier rubber stoppers

Provides special chlorobutyl rubber formula for good compatibility

With pharmaceuticals Special treatment process and the most stringent process control ensure the cleanliness of the rubber stopper

Microbiological testing is to ensure the safety of rubber stoppers