High accuracy CNC machines were developed in response to growing demands for precision, efficiency, and consistency in modern manufacturing. As industries advanced, the need to produce complex parts with tighter tolerances and improved quality became more important. Traditional machining methods, while effective, often lacked the precision and repeatability required for newer applications.

One key factor behind the development of high accuracy CNC machines is the advancement of technology in sectors such as aerospace, medical devices, electronics, and automotive manufacturing. These industries began to require components with extremely fine tolerances, sometimes within microns. Producing such components consistently by hand or with older equipment proved to be challenging. CNC technology, with its ability to follow detailed digital designs, offered a practical solution.

As design software and digital modeling improved, so too did the expectations for part quality. Manufacturers needed machines that could translate highly detailed computer models into physical parts with minimal error. High accuracy CNC machines were developed to meet these expectations, incorporating advancements in control systems, drive mechanisms, and feedback sensors to ensure precise movement and positioning.

Another contributing factor is the demand for greater efficiency and reduced waste. High accuracy CNC machines help minimize material waste by producing parts correctly on the first attempt. They also shorten production times by allowing faster and more reliable machining processes.

https://www.zjgycnc.com/product/vertical-machining-center/linear-way-vertical-machining-center.html

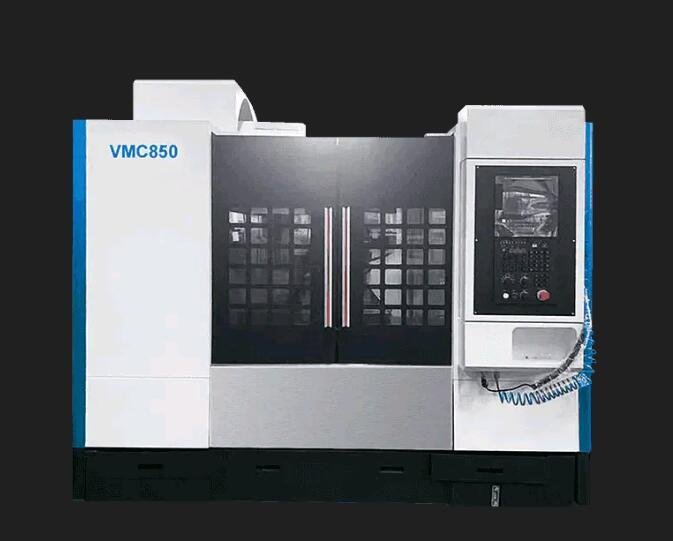

The machine tool is a single-column vertical guideway structure. The column, base, and sliding seat are all made of high-grade gray cast iron resin sand technology. After aging treatment, a 45-roller linear guideway is used in combination with the guideway surface. It has a large bearing capacity, good precision stability, reasonable structure design, and good processing and assembly technology, to ensure the stability and accuracy retention of the machine tool in long-term use.

The spindle of the machine tool is driven by a high torque servo motor, which can not only cut at low speed and high torque, but also can cut at high speed, and meet the requirements of rough machining and finish machining.